Offset Lithographic Printing

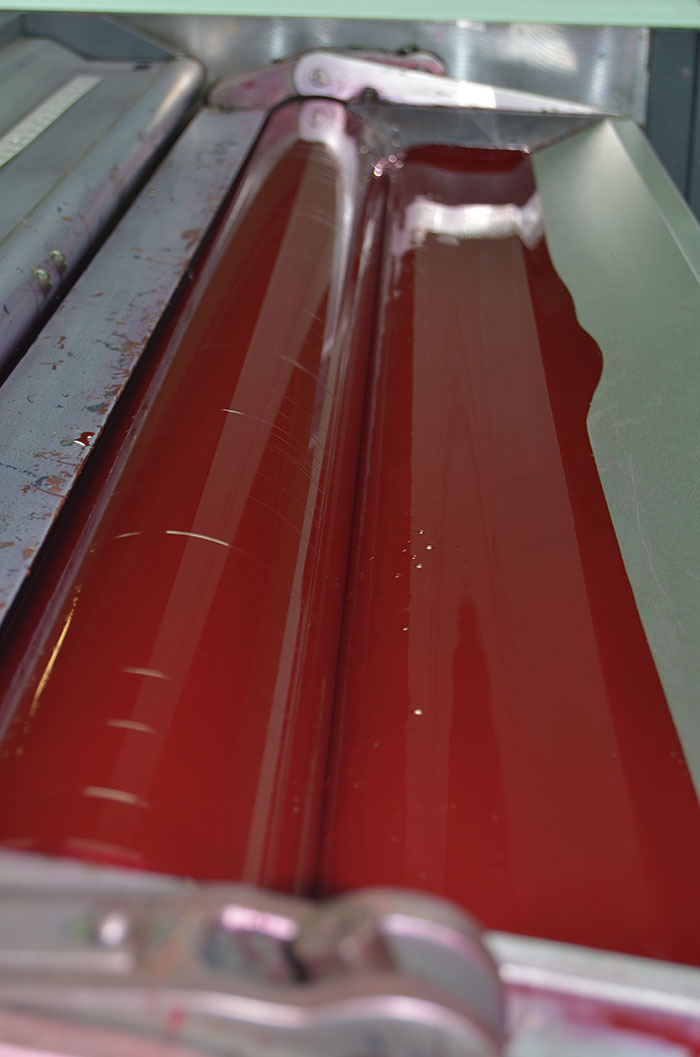

Offset printing is also called lithographic printing. The technique is applied by using the principal of the property of water that is not mixing with oil. On surface of the plate where there is not any image will absorb water. The plate will be kept wet and the ink of print will only adhere to the surface of image area. On each turn of offset cylinders coated with rubber will take the transfer of the printing ink and from there to cylinder holding the plate itself and from there passed to the carton itself. The elasticity of the surface of the offset cylinders will protect the plates’ very tiny delicate pits and let even the specially tectured surfaces of superior papers to take the ink correctly.

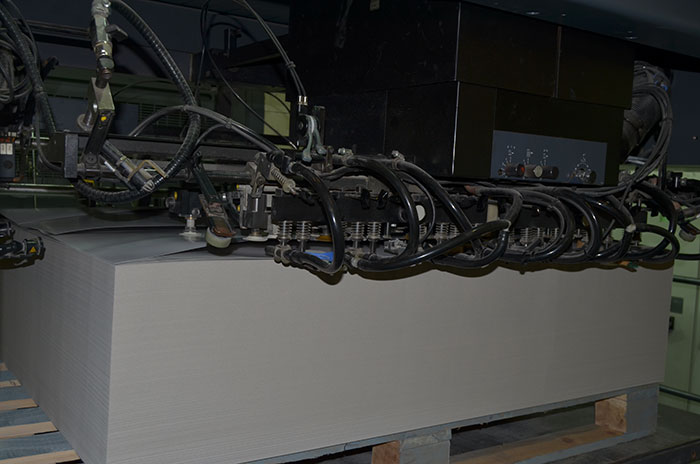

The CTP plates will be fixed to the printing machine and the inks of the CMYK and the extra spot color ink will be added to the supply tank that has been perfectly cleaned from the previous job. The converted carton sheets will be placed on the automatic taking feeder entrance. The machine is set to start the job and will be operated in slow motion to test the preparation stage and the printing of adjusting is done. When the correct printing values are stable on flow, sample sheets are picked and print approval is signed and the fast speed printing will be on action letting upto 16000 sheets per hour fly from one end to the other side of the machine, where the speed is dependent on the carton type and the details of the printing job with the ROLAND 900 HiPrint Format 6B machine accepting a range of thickness 0,1-1,2 mm range slitted sheet size of maximum 1020 X 1420 mm.

One of the two important check points are controlling the blade die-line sample print comparing it with the printed offset carton from the first samples of adjustment sheets. This transparent die-line sample will make it easy to compare if everything matches. If there is any mismatch the machine should be stopped and solution should be applied.

The second thing is the continuous controls of our chiefs on the flow of the job in several intervals to realize if the quality of print and color matching is stable or not. The integration systems we use and the automatic control systems of the machines makes it much easy to track it in this highest technology machines.

Paperboard Folding Box

Paperboard Folding Box Litho-Laminated Box

Litho-Laminated Box Corrugated Box

Corrugated Box Carton Stand

Carton Stand