Our clients have custom design box inquiries and receiving those orders, we first select the carton quality which will effect the display properties of the boxes on the shelves.Outer carton packages will be carrying the goods to prevent the possible damages, maintain the raise of the market share and provide the loyalty to the sales continuity, distinguishing it from competitors while ensuring the visual image quality on the shelves. The products can have direct contact to the carton box, or they can be placed in a prior package before the carton box placement.

The products that will be carried inside our boxes will effect the planning and selection of the hardness of carton, the surface properties, thickness and density of the paper of carton taking into consideration of the usable shelf life, type of material, weight and endurance requirements of the products of our clients. After that, print work, custom cut and folding shape creation, windowing, perforation, embossing, metal color application, coating details and automatic or manual filling properties will be specified and the cartons will be starting its journey in our factory to become a box. Finished boxes will be controlled and packaged and shipped to our clients.

The web rolls of cartons produced in Turkey or in international special cartonboard and paperboard manufacturers can be in many different qualities. Biologically degradable and recyclable rates of those materials are very high and we can claim they are the less harmfull sources used in packaging materials.

There are many competitions held for supporting the design of packaging which helps the creation of visually splendid wonders. Luxurious virgin cartons, layered kraft cartons, from one side or double side coated cartons, on each side two or three times coated cartons, chemically treated and bleached or mechanically formed cartons, foil or film coated barier property added cartons are all can be selected from a range of 180 grams to 995 grams density of thicknesses.

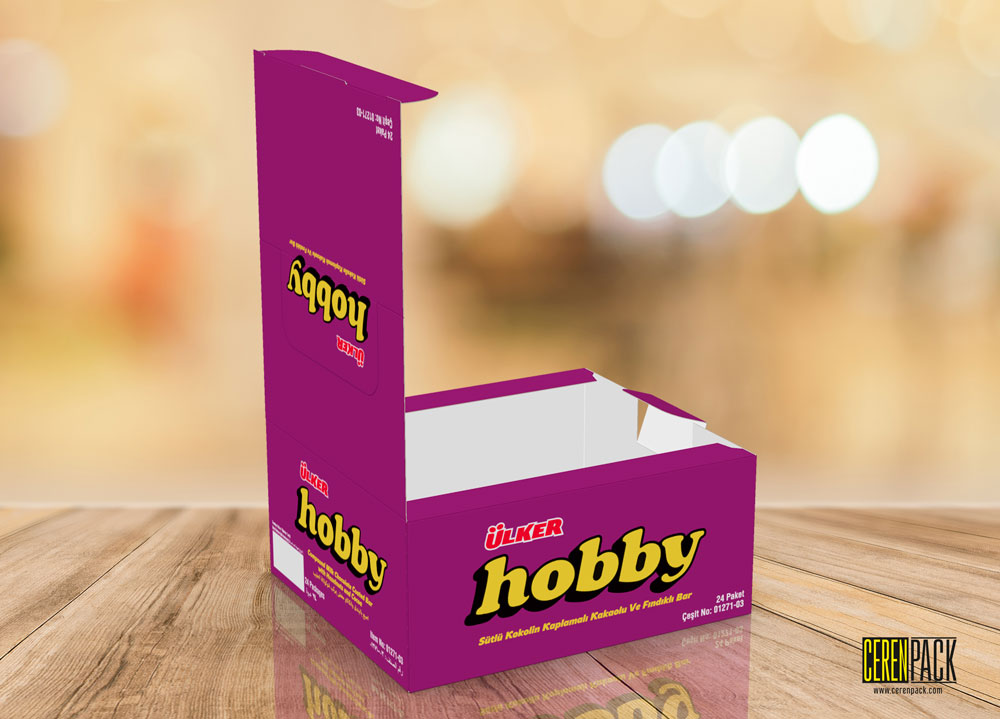

Paperboard Folding Box

Paperboard Folding Box Litho-Laminated Box

Litho-Laminated Box Corrugated Box

Corrugated Box Carton Stand

Carton Stand