The corrugated boxes and chipboard boxes are produced after making the selection of the flute wave type, carton type and density of cartons letting the strength of the box will be suitable for the weight and protection of the material to be packaged.The trade mark perception of the clients is important with the usage of this outside packaging which will carry the multi placement of the inner products.

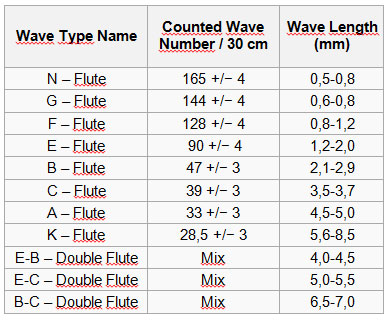

The corrugated boxes are produced from %100 recyclable material. Below mechanical wave properties of the carton box will change the durability of the boxes.

To make it possible to catch the desired stregth of the box, the wave layer can be used as one layer or laminated two layers.

The linerboard Testliner used to carry the layer of the wavy flute carton of recyclable material is the terminological name of the carton and it can be used on both sides. The face surface layer of it or both side can be in different natural brown colors or can be white. In Europe this Testliner can also be called as Wellenstoff.

Linerboard Kraftliner; is a cellulose and virgin based layer paperboard to carry the flute. By definition it is that the fibers over %80 is obtained from chemical sulphate or soda application. Even there are imitation versions. White surface or brown colored versions are available.

Recycled hard wood fiber materials is mostly used in the paper which will be used in flute production called medium.

The products that will be stored in cold chain rooms specially treated NSSC (Neutral Sulfite Semi Chemical) Fluting will be used and it will be resisting vapour and temperature changes. Those boards will be produced by using minimum %65 hard wood fibers semi-chemically bleached.

The linerboards quality will be tested with BCT compression tests and ECT edge crush tests and fluting boards will be tested with CMT surface crash tests. On kraftliner the endurance of the paper against breaking or bursting is more than testliner.

It is limtless to create different designs of box types and shapes. Below you can find a list of the most known types;

Regular Slotted Box. All flaps have the same length and are one half of the box width.

Full Overlap Slotted Box. All the flaps have the same length of the box width and double cover the slots.

Overlap Slotted Box. All the flaps have the same length and outer flaps overlap one inch and more.

Half Slotted Box. Only there are flaps on the bottom side and the upper side is without the flaps.

Center Special Overlap Slotted Box. All flaps have the same length; one half the length of the box.

Tuck Top Box. The flaps of the bottom have manual or automatic sealed type prepared with die cut On up side only 3 flap exists and the big cover flap have a tongue to close inside to the box.

Telescope Box. They are two pieces seperate top and bottom. The top can completely close the bottom or the top can be fitting over the bottom. The covers can from both side which are 3 seperate parts of boxes.

Folder Box. The bottom is closed and they are unbroken bottom surface scoring to fold around the product. The five folds model is widely used. Also roll end trays and self locking ends can be used on this versions.

On carton boxes, one to many colors can be applied and printed on the surface directly or with lamination to give information of the product inside, about the producer and the barcode tracking systems.

Corrugated boxes; are in a range of very sustainable products group which helps protecting the nature and they are very durable, multi purpose, leight weight, suitable for custom design of shapes and very protective for the materials placed inside.

FEFCO European Corrugated Packaging Assocciation is an organisation that defines the standards of the industry and they have declared many different types and designs of shapes and properties. Using the website address http://www.fefco.org/ you can reach valuable information.

FEFCO_ESBO_codes_of_designsFEFCO ESBO CODES OF DESIGN

FEFCO Catalog

Paperboard Folding Box

Paperboard Folding Box Litho-Laminated Box

Litho-Laminated Box Corrugated Box

Corrugated Box Carton Stand

Carton Stand